Interdeck/End of Press UV Curing System

INTERDECK/END OF PRESS UV CURING SYSTEM

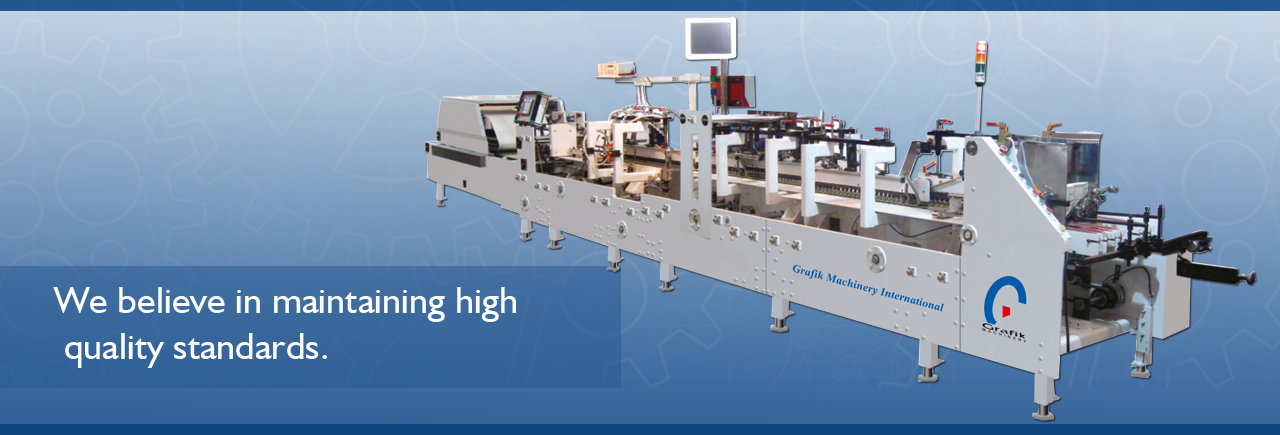

We have been actively engaged in the supplying of the supreme grade of

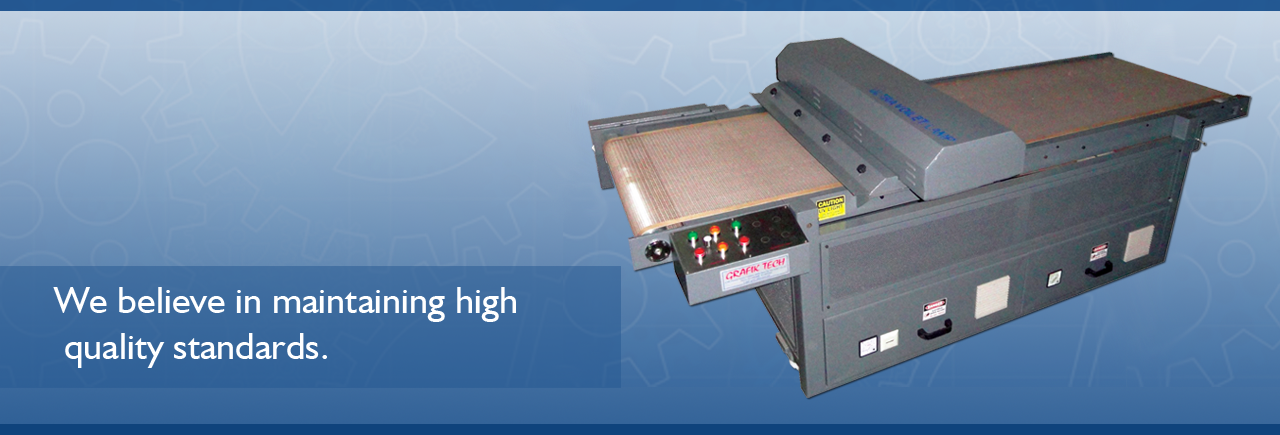

Interdeck / End Of Press UV Curing System which consists pneumatically operated shutter UV cassettes, air and water cooled UV cassettes along with a HMI and PLC controlled panel. In this system all operational and status function integrated on HMI screen. Integration of this panel with main machine is done for activation of shutter system whereas the reduction takes place in output power of UV lamps. Interdeck / End Of Press UV Curing System has overheating safety system for cassettes. It is mainly used in packaging industry.

Features:

- Pneumatically operated shutteres UV cassettes

- Air and water cooled UV cassettes

- UV lamp- 300-400 W/Inch

- Over heating safety system for cassettes

- HMI and PLC controlled panel

- All operational and status function integrated on HMI screen. Integration of panel with main machine for activation of shutter system and reduction in output power of UV lamps.

Optional Equipment:

- Electronic Power Supply for UV Lamp

Applications:

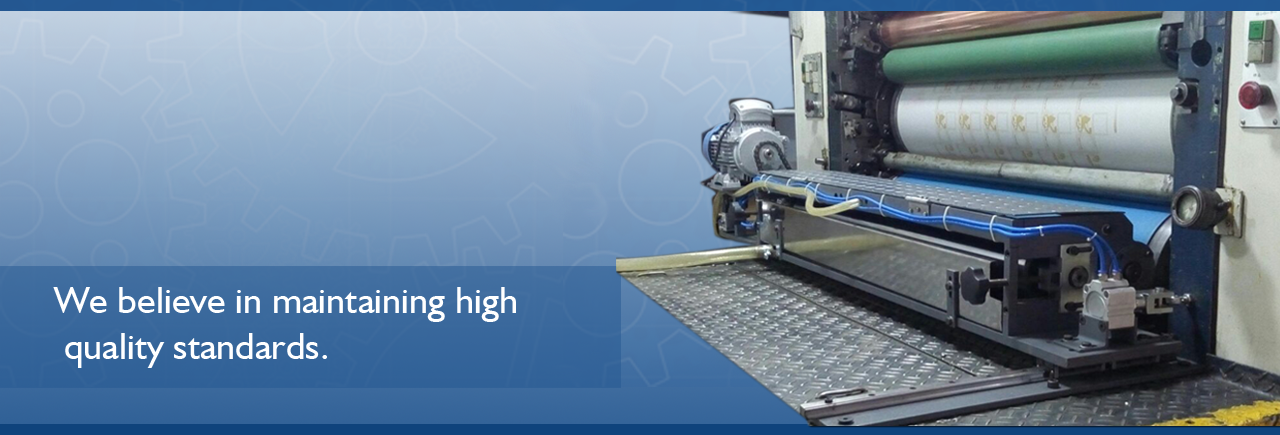

- For Full/Spot UV coating and frip off coating on offset machine with coater

- Sheet-feed offset machine-for printing on MET-PET, PP, PVC and other non absorbent surfaces

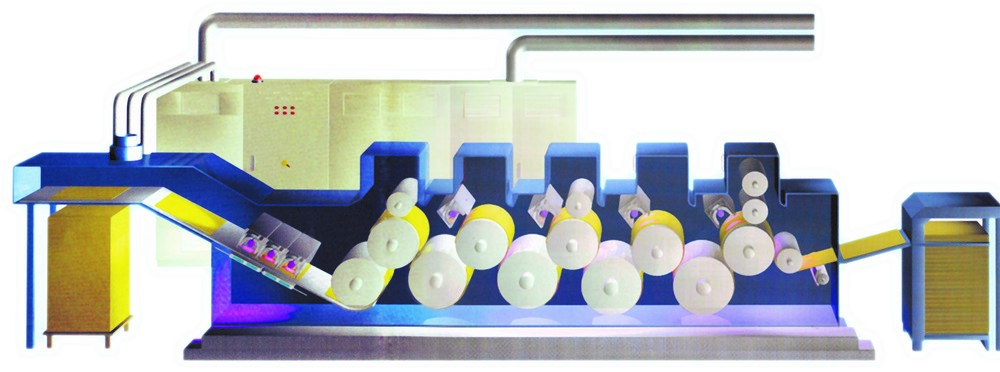

- Narrow, wide web Flexo machines

- Rotogravure machine

UV curing is a printing technology used mainly in packaging industry, as it can be applied on any material. This printing technology is employed for creating attractive packing, so that market value of the packaged material can be enhanced. Our company, Grafik Machinery International, makes available interdeck/ end of press UV curing system, which can be attached to offset machine of any make and size. UV inks can be dried instantly with the installed dried between the printing units of a press. UV curable inks are ideal for printing on non-absorbent surface. Interdeck/ end of press UV curing system cures the first UV coat before applying the second one in case when special effect abrasive UV coating is to be applied on the printed surface.

Enquiry