UV Coating Machine Adast Dominent

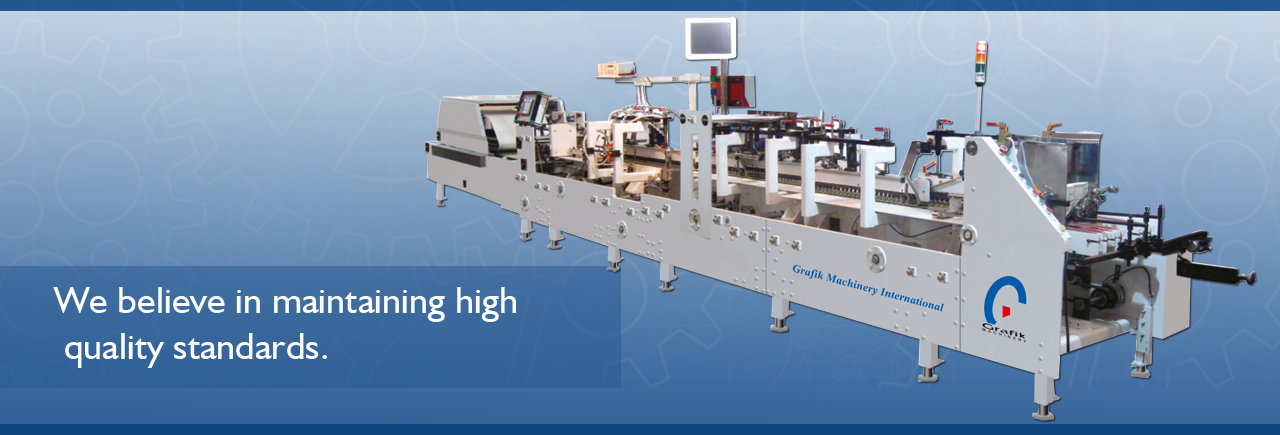

Print Plus Coat- Coating Machine is an impressive solution offered by Grafik Tech. These are engineered to perfection by a team of expert engineers, designs and technicians. They utilize cutting-edge technologies and highest grade metal alloys, sourced from reliable vendors. Print Coating System offered by us are reasonably priced for heavy duty constructional purposes. The features of printing provided by these remain unchanged and can be highly reliable. We deliver Coating Machine in specifications that match with the desired requirements of individual press. The fluency in operations, negligible maintenance, user-friendly applications and longer service life are the various attributes that make our offered Print Coating System preferred by clients.

- Heavy duty construction

- Manual retraction system to change between printing and coating

- Independent AC motor and frequency drive

- Pneumatic Impression synchronized with main machine

- Varnish recirculation system with drip tray

Advantages:

- Uniform coating thickness with greater efficiency and repeatability.

- Easy to register and high production.

- Full as well as Spot Varnishing possible.

- Printing features of the main machine remains unchanged, as the system is independent.

- The total investment is negligible as compared to other options.

- Can be fitted on sheet fed offset of any make and size.

- Custom engineered to fit individual press.

Options:

Chamber doctor blade system

Versatile Application Capability

The Adast Dominent UV Coating Machine is engineered to handle a wide array of substrates, including paper and cardboard, making it perfect for offset printed jobs, catalogs, and commercial print assignments. Its compatibility with both full and spot UV coating techniques provides impressive flexibility to meet diverse client requirements.

Efficient Performance & Automated Operation

With its automatic feeder and PLC controlled system, this machine delivers outstanding productivity, processing up to 3000 sheets per hour. The hard chrome plated roller system ensures durability and even coating, while the advanced drying system guarantees reliable results at high speeds.

Safety and Low Maintenance Features

Safety is addressed with an emergency stop button and overload protection, providing peace of mind for operators. The machine boasts low maintenance requirements and is designed for effortless cleaning, meaning minimal downtime and sustained performance.