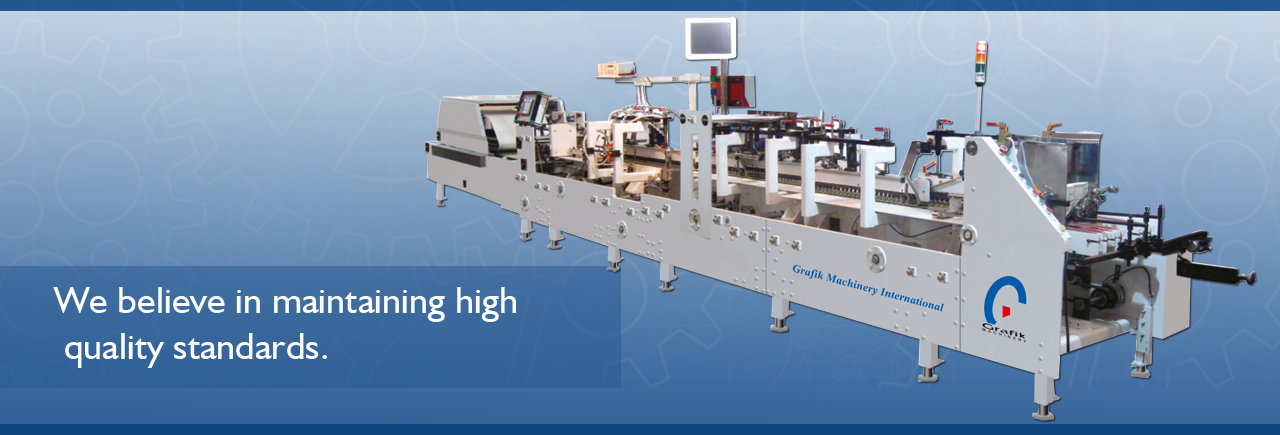

Carton Folder Gluer

Carton Folder Gluer

Grafik Machinery International delivers an astonishing array of Carton Folding & Gluing Machines which are designed to perfection to deliver bulk productions within minimal cost and budget. We have employed a state-of-the-art infrastructural premise and team of experienced staff who underline the strict norms and standards of the industry to deliver optimum grade solutions for Carton Gluing Machine. These are widely preferred across the paper and packaging industries for their immense fluency of operations, minimal maintenance, sturdy designs and extended functional life.

Technical Specification:

| Model | Min.Width (Open Blank ) | Max. Width (Open Blank ) | Power Required | Dimensions | Max. Speed |

| GRAFIK-35 | 60mm | 350mm | 5.0HP | 0.85 x 7.0 Meters | 250Mtrs/min |

| GRAFIK-45# | 75mm | 450mm | 5.0HP | 1.15 x 7.0 Meters | 250Mtrs/min |

| GRAFIK-65# | 80mm | 650mm | 5.0HP | 1.2 x 7.0 Meters | 250Mtrs/min |

Salient Features | Optional Features | Special Purpose Machines |

Maximum Speed 250 mtr/min | Crash lock bottom attachment | Sleeve pasting Machine for match box,harpner ,ewing gum boxes etc |

Easy to opearate | Totalizer & batch counter | Corrugated cartons-folding and gluing. |

AC variable frequency drive | Electronic nozzle gluing system |

|

Less ChangeOver Time |

|

|

100% per folding |

|

|

Feeder Electro magnetic clutch |

|

|

Precision Folding Meets Robust Automation

This folder gluer combines precise folding methodsstraight line and crash lock bottomwith dependable automated operation. Built with a flatbed plate and mild steel structure, it delivers long-term reliability for industrial-scale operations. The uni-directional print capability and PLC control system ensure that every carton is folded and glued consistently and accurately.

Versatility in Carton Sizes and Glue Types

Accommodating a wide range of carton sizes from 100 x 60 mm to 900 x 650 mm, this machine adapts seamlessly to diverse packaging requirements. Its compatibility with both hot melt and cold glue enhances its suitability for various packaging materials and industry standards, ensuring strong bonds and clean finishes on each box.

Safety and Efficiency at Its Core

Engineered with protective covers and an emergency stop feature, the machine emphasizes operator safety without sacrificing productivity. Its automatic feeder and conveyor system streamline the workflow, minimizing manual intervention and supporting a throughput of up to 12,000 boxes per hour while maintaining a noise level below 80 dB for a more comfortable working environment.