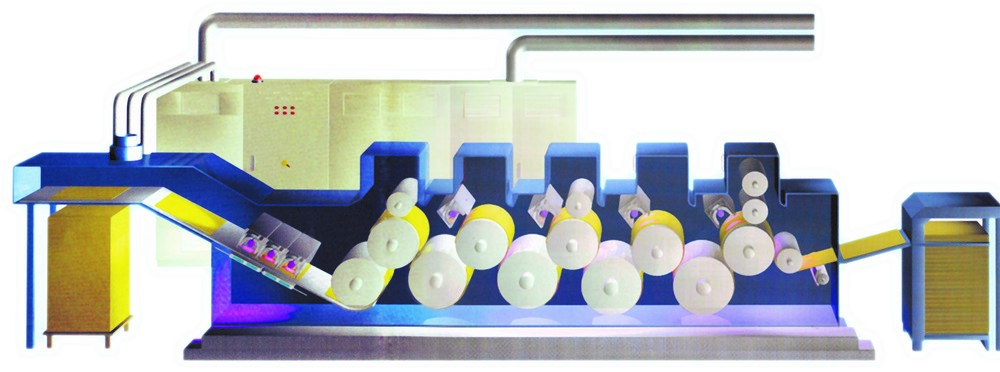

Interdeck/End of Press UV Curing System

INTERDECK/END OF PRESS UV CURING SYSTEM

We have been actively engaged in the supplying of the supreme grade of

Interdeck / End Of Press UV Curing System which consists pneumatically operated shutter UV cassettes, air and water cooled UV cassettes along with a HMI and PLC controlled panel. In this system all operational and status function integrated on HMI screen. Integration of this panel with main machine is done for activation of shutter system whereas the reduction takes place in output power of UV lamps. Interdeck / End Of Press UV Curing System has overheating safety system for cassettes. It is mainly used in packaging industry.

Features:

- Pneumatically operated shutteres UV cassettes

- Air and water cooled UV cassettes

- UV lamp- 300-400 W/Inch

- Over heating safety system for cassettes

- HMI and PLC controlled panel

- All operational and status function integrated on HMI screen. Integration of panel with main machine for activation of shutter system and reduction in output power of UV lamps.

Optional Equipment:

- Electronic Power Supply for UV Lamp

Applications:

- For Full/Spot UV coating and frip off coating on offset machine with coater

- Sheet-feed offset machine-for printing on MET-PET, PP, PVC and other non absorbent surfaces

- Narrow, wide web Flexo machines

- Rotogravure machine

UV curing is a printing technology used mainly in packaging industry, as it can be applied on any material. This printing technology is employed for creating attractive packing, so that market value of the packaged material can be enhanced. Our company, Grafik Machinery International, makes available interdeck/ end of press UV curing system, which can be attached to offset machine of any make and size. UV inks can be dried instantly with the installed dried between the printing units of a press. UV curable inks are ideal for printing on non-absorbent surface. Interdeck/ end of press UV curing system cures the first UV coat before applying the second one in case when special effect abrasive UV coating is to be applied on the printed surface.

Achieve up to 99% full-cure on a variety of substrates with the advanced high-intensity UV lamp technology. Whether printing on paper, board, film, or PVC, the system guarantees uniform and reliable results, enhancing product quality and consistency.

Flexible Installation OptionsDesigned for seamless integration, the UV curing system supports both inline and end-of-press installation. This flexibility allows for compatibility with diverse printing machines and workflows, including sheetfed offset, flexo, and web presses.

Enhanced Safety and ControlWith features like overheat protection, interlocks, and integrated PLC control, operators benefit from a safe and easy-to-manage system. The advanced color management capability ensures accurate color reproduction and dependable performance.

FAQs of Interdeck/End of Press UV Curing System:

Q: How does the Interdeck/End of Press UV Curing System achieve 99% full-cure efficiency?

A: The system utilizes a high-intensity UV lamp that rapidly and thoroughly cures UV curable inks on substrates such as paper, board, film, and PVC. Advanced color management and precise temperature control guarantee consistent curing results and optimal print quality.

Q: What types of substrates can be processed using this UV curing system?

A: This curing system is suitable for a wide range of substrates, including paper, board, film, and PVC, making it highly versatile for different print applications across various industries.

Q: When should the UV lamp be replaced, and what is its expected lifespan?

A: The high-intensity UV lamp typically lasts between 2000 to 4000 hours, depending on operational intensity and maintenance practices. Replacement is recommended when curing performance diminishes or within the specified lifespan to ensure consistent results.

Q: Where can this UV curing system be installed in a printing workflow?

A: Installation is flexibleyou can integrate the system inline within the printing process or at the end of press. This enables it to accommodate both continuous and batch processing setups for sheetfed offset, flexo, and web presses.

Q: What is the process for maintaining this UV curing system?

A: The system features a low maintenance design with easy-to-access components. Routine inspections of cooling systems, lamp condition, and cleaning of air/water filters are usually sufficient to keep the system in optimal condition.

Q: How does the system ensure operator safety during operation?

A: Safety measures such as overheat protection, interlocks, and integrated PLC control help prevent accidental exposure, overheating, and unauthorized access, creating a safer working environment.

Q: What are the benefits of using this automated UV curing system?

A: Users experience rapid curing speeds (up to 8000 sheets per hour), reduced downtime, precise color management, and customizable capacity. The automated setup and computerized control simplify operation, leading to enhanced productivity and consistent output quality.