LED UV System

LED UV System

Advantages:

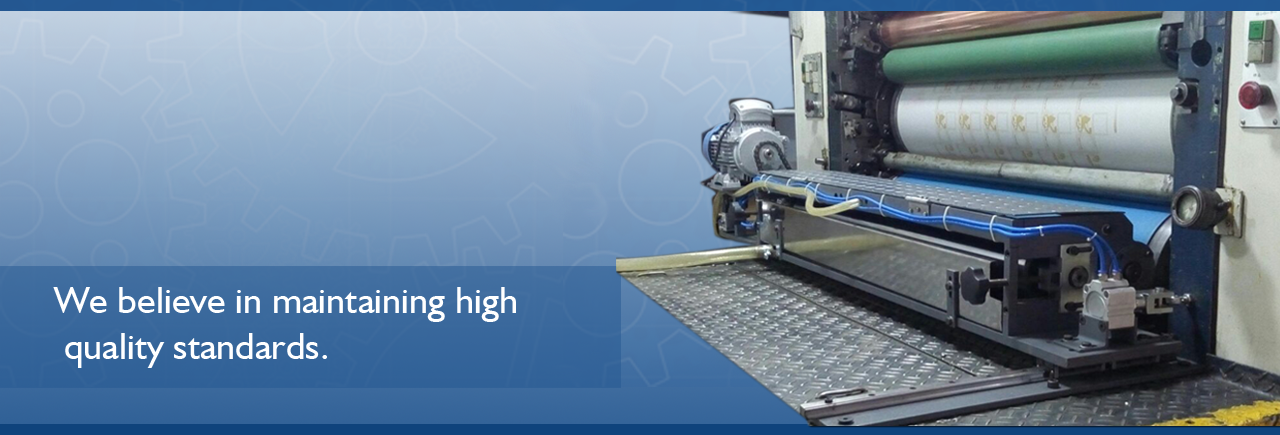

- Low Operating Temperatures

- Energy Savings up to 75%

- Mercury and Ozone Free

- Suitable for Heat Sensitive subsrates also.

- Flexible Curing widths / Scalable

- Better Adhesion and Curing Capabilities

- Increased Production quality

Features:

- High peak Irradiance

- Air and Water cooled system

- Lamp life of upto 5,000 hrs.

- Easy Maintenance

- Operates on single phase

- Instant Start & Stop

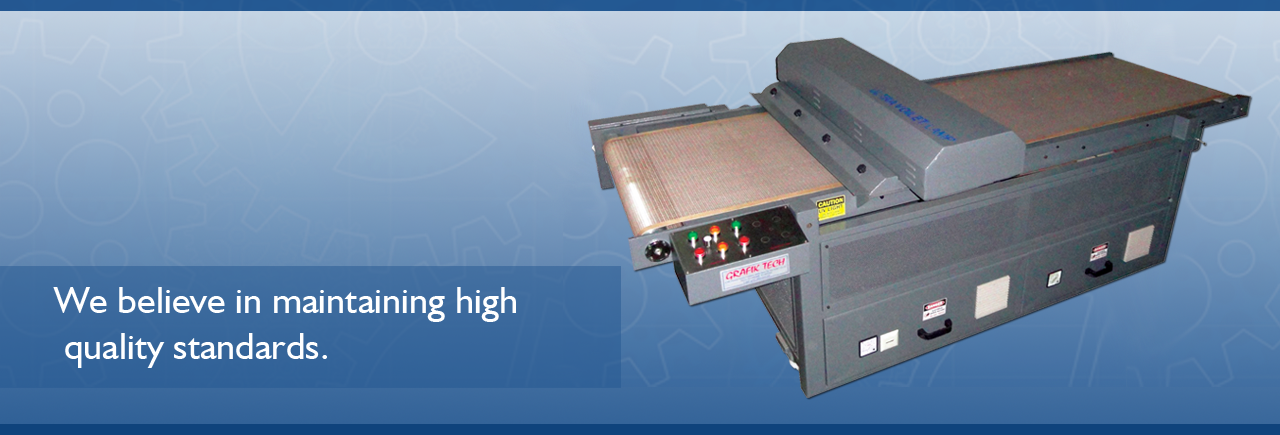

- Compact Size, makes installation easier

- Width wise zone control

Applications :

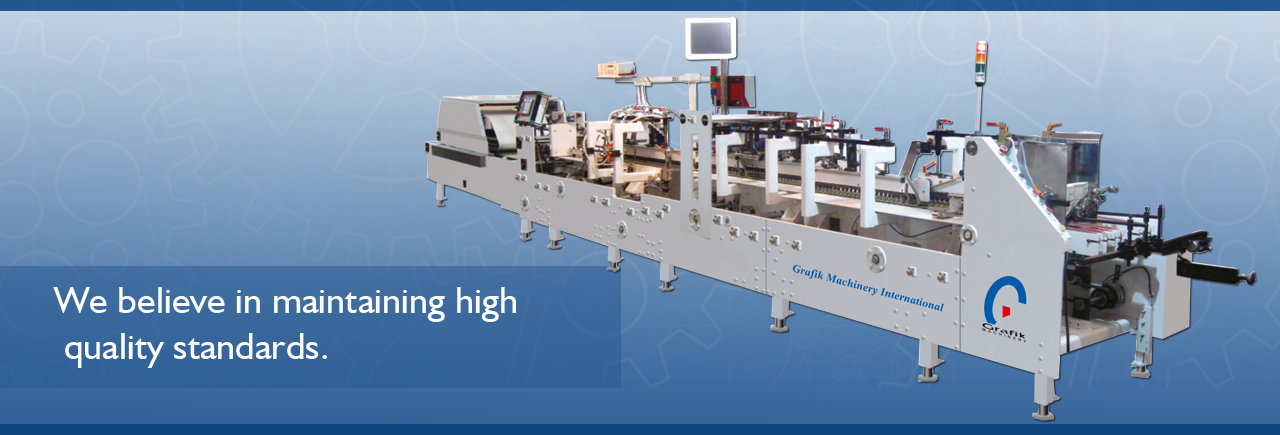

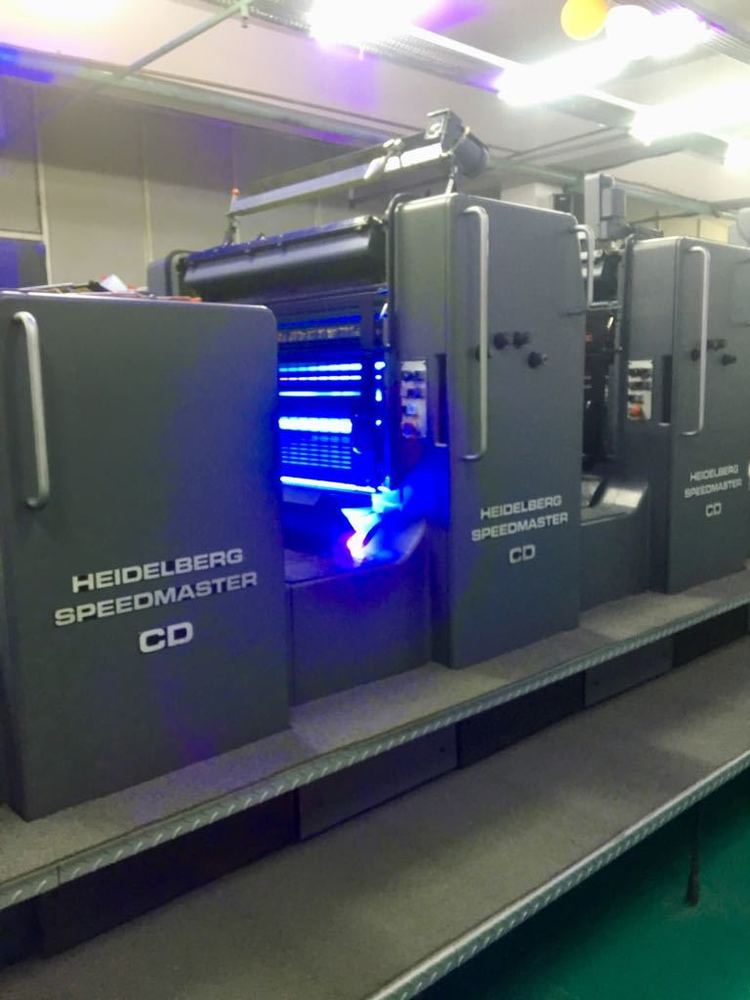

- Sheet fed Offset Machines

- Flexo Machines- Narrow and wide web

- Screen printing machines

- UV Coating machines

Comparision Table:

| Features | UV-LED | UV-MERCURY |

| Lamp life | upto 5,000 hrs | 1000-1500 hrs |

| Heat Generation | No | High |

| Intensity control | 0-100% | 10-100%(with EPS) |

| Size | Compact | Heavy |

| Start-up time | Instant | 3-4 minutes |

| Energy consumption | Low | High |

| Environment Friendly | Yes | No |

LED UV System is put to use when inks, paints or clear coats are to be instantly dried, or adhesives to be cured in bonding or sealing processes. Ultraviolet energy is used for changing a liquid into a solid. A polymerization reaction is caused as UV energy absorbs, which changes the UV material into solid. UV LED curing method is better than any traditional drying method, as it delivers several benefits, for instance environmentally friendly, high-end functionality, increased efficiency, ensured safety, and long service life. In comparison to UV-mercury, UV-LED has better lamp life, more compact size, instant start-up time, lower energy consumption, and doesn't generates heat. The system is mainly used with special printing and coating machines. Companies whose requirements are quick and efficient curing in applications that involve printing inks,coatings and adhesives, can install LED UV System.

Premium UV Intensity for Professional Applications

Engineered for versatility and performance, this LED UV System outputs a UV intensity of 8,000 mW/cm. Ideal for UV printing, quick curing, and adhesive drying, it ensures precise and uniform results. The narrow beam angle enhances application accuracy, delivering reliable outcomes across your industrial workflows.

Advanced Cooling and Protection Technology

The systems active fan and heat sink guarantee optimal thermal management, maintaining efficiency even during extensive use. Integrated over-voltage, over-current, and thermal protection features provide safeguarding, while the aluminum alloy housing ensures durability in harsh environments.

Flexible Operation and Seamless Integration

Offered with both onsite and remote service support, the unit also features adjustable mounting via bracket arm and waterproof industrial connectors for easy installation. Manual and remote controls (up to 20 meters) enable seamless usability, and the modular design accommodates diverse industrial needs.