Roller Coater

Roller Coater

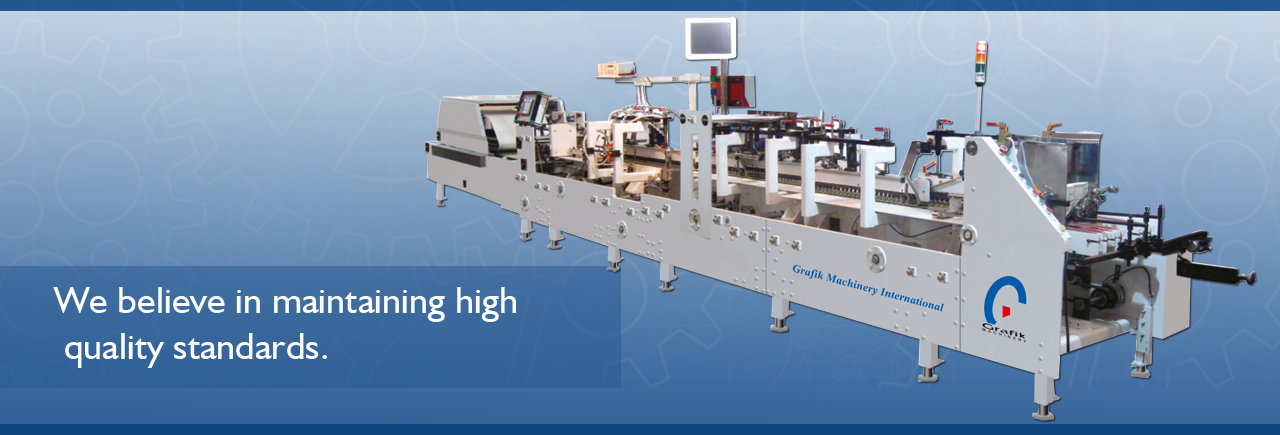

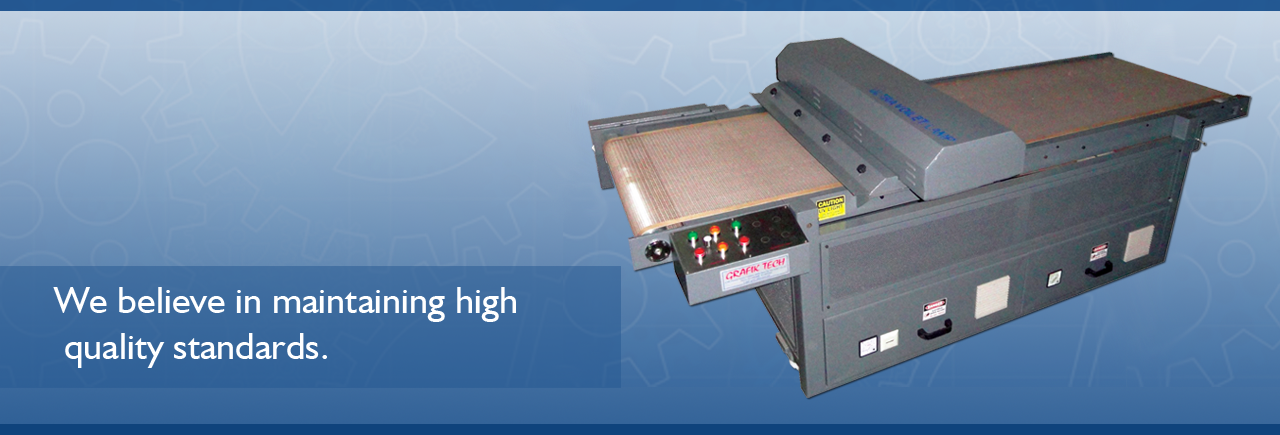

If you are looking for energy efficient Roller Coater Machine, then this is perfect for you. We are Grafik Machinery Exchange India, one of the reputed manufacturers of hot melt roller coater, which is used for UV lacquers and water based varnish for producing best quality finishes on different printed substrates. The machine is provided with sheet stacking system and is loaded with many other features, which makes it a best product. The Grafik Roller Coater Machine is known for coating the heaviest of substrates that too in the most rugged environments. In addition, it is used for its precision in achieving top level of accuracy of coating weights. It has durable, heavy duty steel construction and it can provide service 24x7.

Features:

Features:

- AC Motor with a frequency drive

- Adjustment of precession coating metering is possible

- Coates 180 gsm - 400 gsm paper stock

- Durable construction and good resistance against corrosion

- Electronic coating control system

- For varnish, recirculation system is provided

- High energy efficiency and simple operation

- IR and UV Driers

- Polished and hardened chrome doctor along with impression rollers

- Sheet stacking system

- Speeds up to 4000 iph

- Variable speed

- Zero-make ready time

Precision Coating for Versatile Applications

This Roller Coater is engineered for versatility, capable of coating wood, metal, and plastic sheets with adjustable thickness. The robust stainless steel roller, combined with an automatic lubrication system, ensures consistent surface finishing whether youre handling furniture panels or industrial metal sheets. With the computerized PLC control system, operators can effortlessly customize settings for a wide range of substrate sizes and types.

Advanced Safety and Ergonomic Design

Safety is prioritized through features like emergency stop and overload protection, ensuring secure operation in busy industrial settings. The noise level remains at or below 78 dB, fostering a safer work environment. Heavy-duty transport wheels and a digital touchscreen make the equipment both mobile and user-friendly, streamlining setup and daily operation.