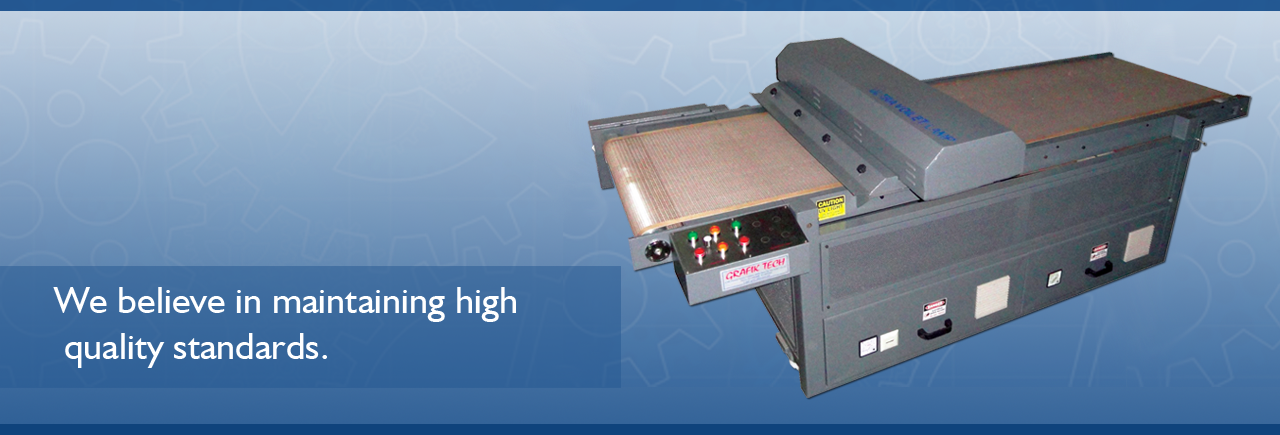

U.V Curing System

U.V Curing System

From the river of our pearl products, we bring forth for our clients U.V. Curing system that uses UV inks for printing on plastic, metalized paper and electronic circuit boards. Manufactured using high quality components, these U.V Curing Machines is designed in a manner so that it can be adapted on any coating process, namely, sheet fed offset, letter press, silk screen and varnishing machine. Further, provided U.V. Curing System can be purchased from us at most competitive price.

Features:

- Air cooling system

- COLD UV Curing system for heat sensitive substrate

- Delivery tray

- Easy access to lamp housing with quick and easy to fit lamps

- Enhanced durability

- High pile delivery/ stacker delivery

- Hood safety interlock & thermal cut off

- Hour counter & Ampere meter

- I.R.Drier

- Over current sensor and Belt jamming sensor

- Powder coated finish

- PTFE coated Heat Resistant belts

- Sheet counter

- Two lamp system on specific order

- Up to three power levels for lamp output power

- UV Curing system for UV Ink printing

- Vacuum suction to hold down the substrates

- AC Frequency drive Conveyor of Variable speed with 0 to 75 Mtrs./Min speed

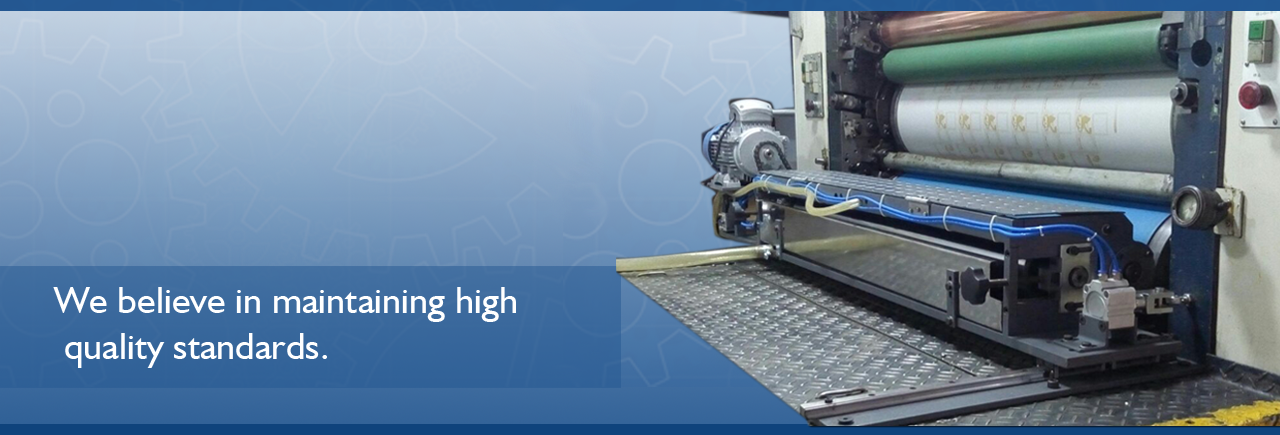

The 'Grafik Tech' U.V Curing Machines can be fitted on Rotary Printing Processes i.e., Flexo, Roto-Gravure and Web Offset Machines for both full coating and spot coating. The "Grafik Tech" U.V. Curing System can be designed for any other specific purpose and client's requirements, for both Online and Off-line uses. The Lamps used are ozone free Lamps.

The 'Grafik Tech' U.V Curing Machines are also available for heat sensitive substances.

Technical Specifications

| Model | Curing Width in inches | Conveyor Size in inches | Lamp Power in w/inch | Power Consumption UV (Full Power) single Lamps | Power Consumption |

| GT 18 | 18 | 22 x 72 | 300 | 5.4 kw | 6 kw |

| GT 25 | 25 | 29 x 72 | 300 | 7.5 kw | 7.5 kw |

| GT 30 | 30 | 34 x 72 | 200/300 | 6/9 kw | 9 kw |

| GT 32 | 32 | 36 x 72 | 300 | 9.6 kw | 9 kw |

| GT 40 | 40 | 44 x 72 | 300 | 12 kw | 12 kw |

Advanced Curing Flexibility

With a choice between mercury vapor and LED UV lamps, the system allows you to configure 2 to 4 lamps for optimal curing. This flexibility accommodates a wide range of substrates and ink types, ensuring superior print adhesion and finish across diverse applications.

Reliable & Efficient Operation

Engineered with digital LCD panel, PLC-based controls, and overload protection with interlocking safety features, the system operates smoothly even in demanding production conditions. The durable powder-coated body, stainless steel and mild steel construction, heavy-duty wheels, and customizable capacity ensure longevity and operational ease.

Eco-Friendly and User-Focused

Benefit from a low emission, environmentally conscious design, supported by air-cooled or water-cooled options. The system minimizes its environmental impact while delivering high productivity, making it ideal for modern, responsible printing businesses. On-site installation support further enhances user experience.