UV Coating Machine Heidelberg

UV Coating Machine Heidelberg

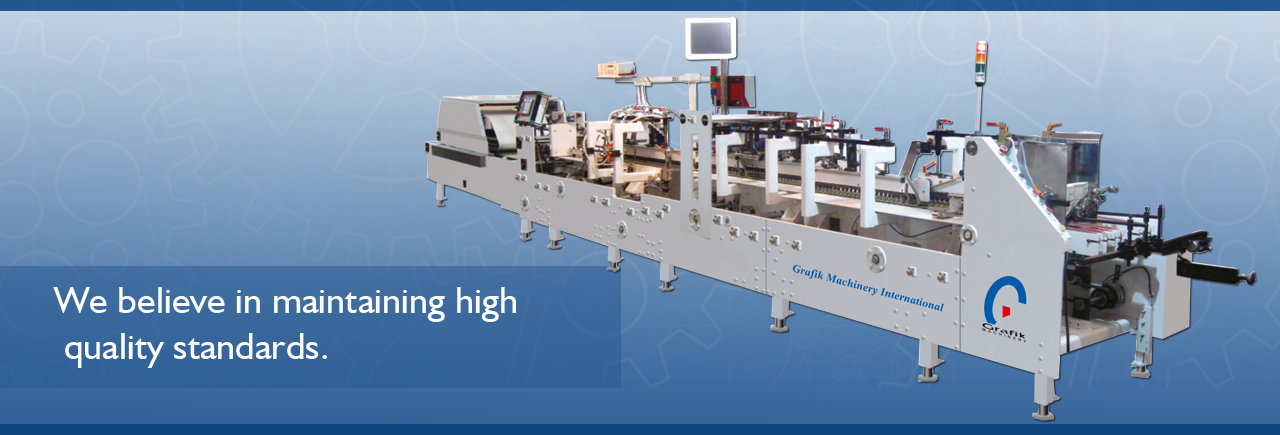

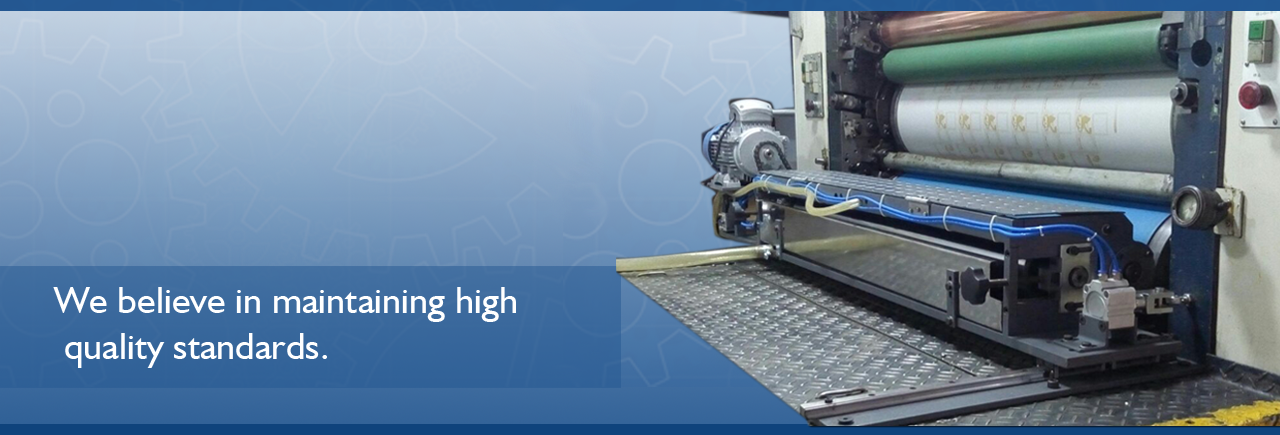

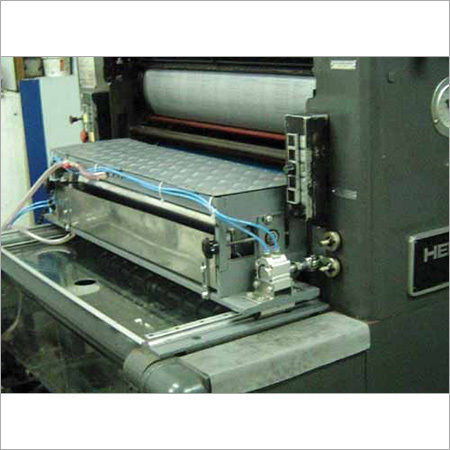

By following the heavy duty construction finest grade of UV Coating Machine Heidelberg is manufactured. This machine is equipped with independent AC Motor and frequency drive, the pneumatic impression is synchronized with main machine as well. Offered machine gives high production and is easy to register. It can be fitted on sheet fed offset of any make and size. This grade of UV Coating Machine Heidelberg has number of printing features of the main machine which remains unchained as the system is independent. Our esteemed clients can avail this well functioning machine in different technical specifications as per their requirements at highly affordable market rates.

Features:

- Heavy duty construction

- Manual retraction system to change between printing and coating

- Independent AC motor and frequency drive

- Pneumatic Impression synchronized with main machine

- Varnish recirculation system with drip tray

Advantages:

- Easy to register and high production

- Full as well as Spot Varnishing possible

- Printing features of the main machine remains unchanged, as the system is independent

- The total investment is negligible as compared to other options

- Can be fitted on sheet fed offset of any make and size

- Custom engineered to fit individual press

Options:

Chamber doctor blade system

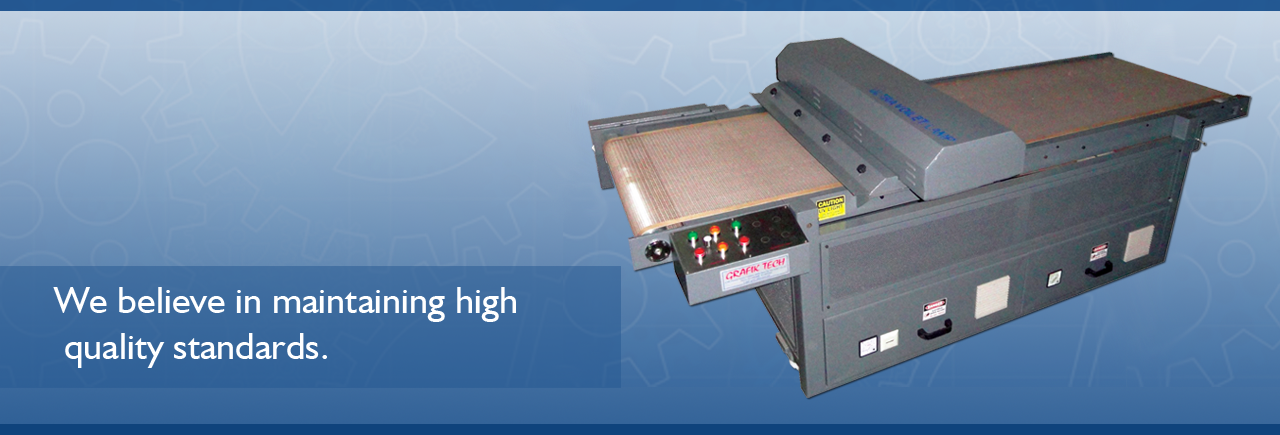

High-Precision UV Coating Across Multiple Materials

The Heidelberg UV Coating Machine is engineered for accuracy and versatility, accommodating paper, board, and non-porous materials within a maximum sheet size of 720 x 1020 mm. The adjustable coating thickness (312 microns) allows for tailored finishes, whether spot or full-surface, ensuring compatibility with diverse printing needs.

Efficiency and Safety at Industrial Scale

With automatic feeding, a rapid drying system, and a processing speed of up to 7000 sheets per hour, this machine maximizes productivity. Essential safety features such as emergency stop and overload protection are integrated, along with ergonomic access for routine servicing and user-friendly PLC touch screen controls.

Integrated Color Management and Modern Control

The systems computerized controls and integrated color management ensure consistent, high-quality results. Operators benefit from real-time adjustments through the touch screen PLC interface, helping maintain quality standards while optimizing workflow.