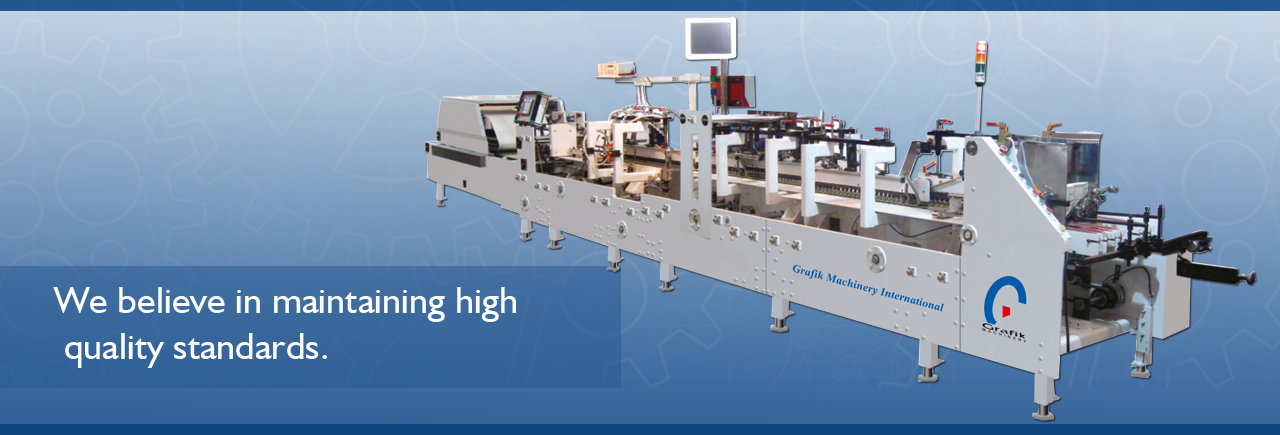

UV Coating Machine KBA

UV Coating Machine KBA

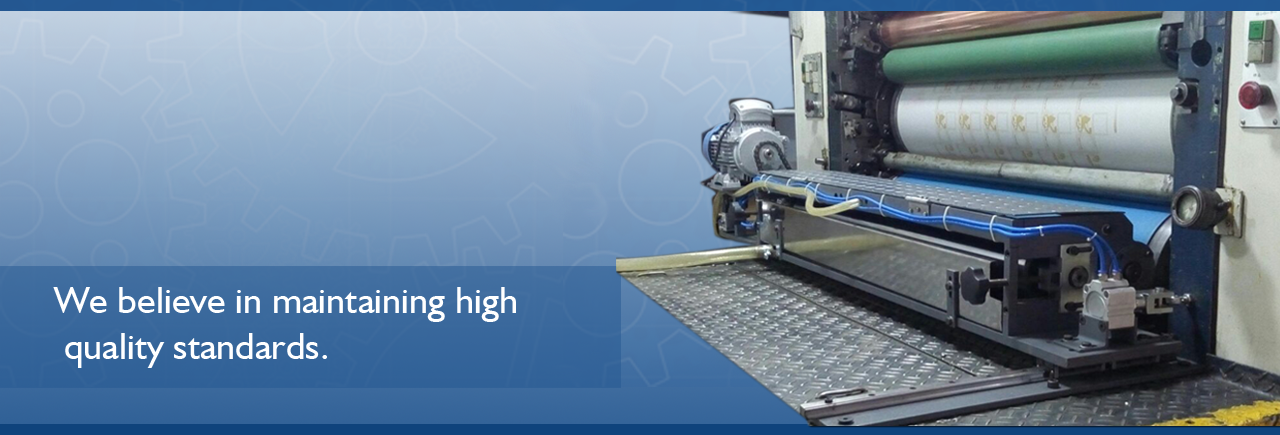

Offered UV Coating Machine KBA is a varnish recirculation system with drip tray, which offers pneumatic impression which is synchronized with the main machine. With the utilization of optimum quality metal as raw materials under the advanced technologies.

This machine has an uniform coating over it with greater efficiency and repeatability.

Offered UV Coating Machine KBA is customized in different forms so that it get fit into individual press. This grade of machine is also available with the chamber of doctor blade system and can be ordered at reasonable market rates. Printing features of the main machine remains unchanged, as the system is independent.

Features:

- Heavy duty construction

- Manual retraction system to change between printing and coating

- Independent AC motor and frequency drive

- Pneumatic Impression synchronized with main machine

- Varnish recirculation system with drip tray

Advantages:

- Uniform coating thickness with greater efficiency and repeatability

- Easy to register and high production

- Full as well as Spot Varnishing possible

- Printing features of the main machine remains unchanged, as the system is independent

- The total investment is negligible as compared to other options

- Can be fitted on sheet fed offset of any make and size

- Custom engineered to fit individual press

Options:

-

Chamber doctor blade system

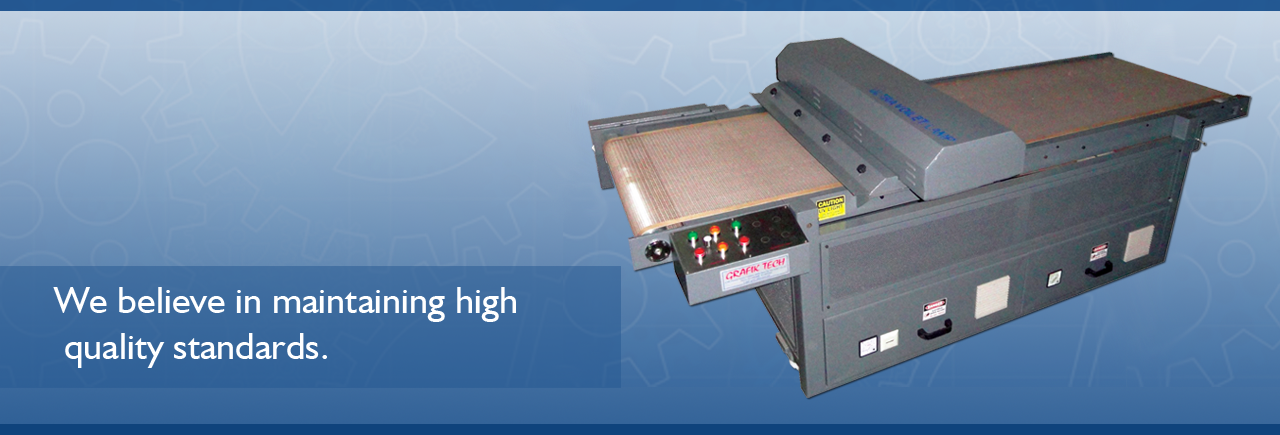

High-Precision Coating for Professional Results

Engineered for versatility and accuracy, the KBA UV Coating Machine delivers consistent surface finishes in glossy, matte, and spot UV effects. Its advanced coating control allows uniform application from 3 to 15 microns, catering to diverse commercial print requirements on paper, board, or plastic materials.

Efficient Operation and Seamless Automation

This automatic sheet-fed machine maximizes throughput with a capacity of 2,000 sheets per hour. Integrated with a digital panel and PLC control, workflows are streamlined for both novice and expert operators, enhancing productivity with minimal manual intervention.

Reliable Construction and Enhanced Safety

Constructed from heavy-duty steel, the KBA UV Coating Machine is built for longevity while maintaining safety as a priority. Features such as emergency stop switches and overload protection, paired with a low noise level below 75 dB, provide a secure and comfortable working environment.

Value-Added Service and Support

Distributors and suppliers in India provide comprehensive onsite installation, user training, and ongoing support. With low maintenance requirements and readily available assistance, the KBA UV Coating Machine remains dependable for continuous, high-volume production.