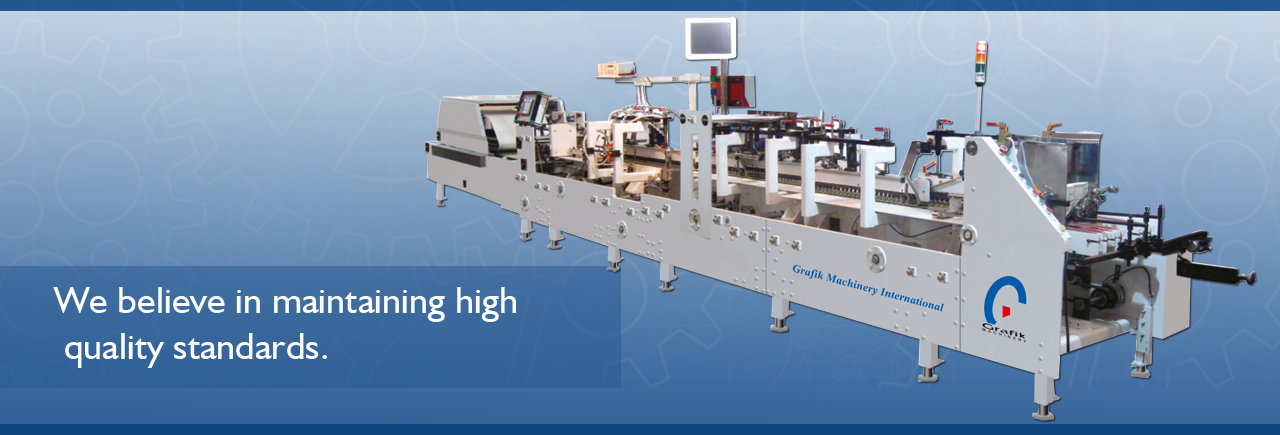

UV Coating Machine Komori

UV Coating Machine Komori

Features:

- Energy efficient

- Simplified handling

- Longer functional life

- Robust construction

- Heavy duty construction.

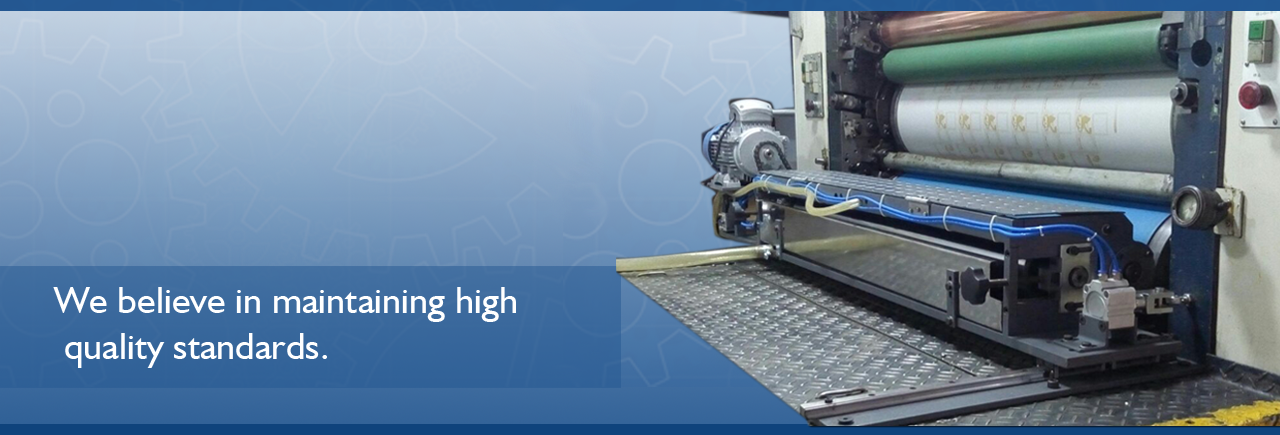

- Manual retraction system to change between printing and coating.

- Independent AC motor and frequency drive.

- Pneumatic Impression synchronized with main machine .

- Varnish recirculation system with drip tray.

Advantages:

- Uniform coating thickness with greater efficiency and repeatability.

- Easy to register and high production.

- Full as well as Spot Varnishing possible.

- Printing features of the main machine remains unchanged, as the system is independent.

- The total investment is negligible as compared to other options.

- Can be fitted on sheet fed offset of any make and size.

- Custom engineered to fit individual press.

Options:

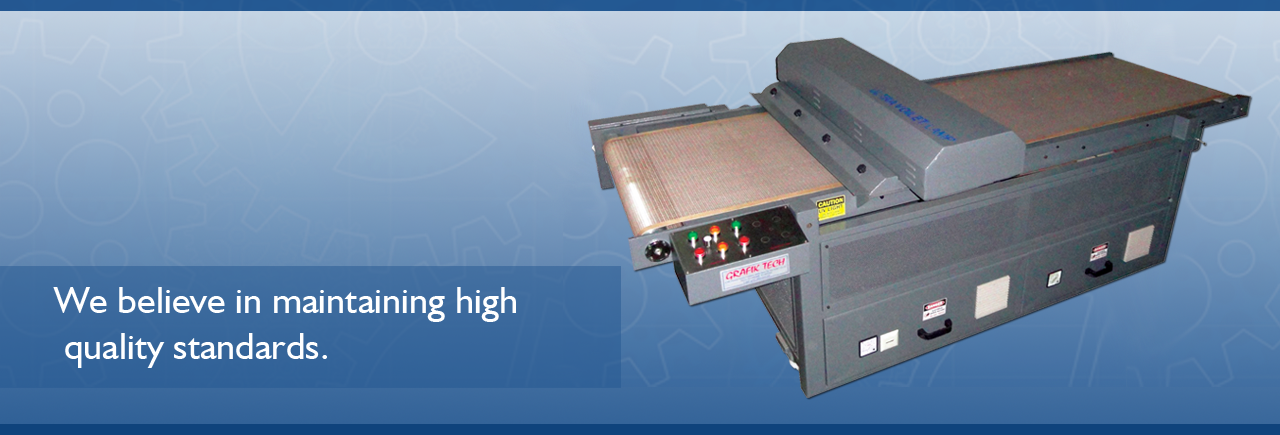

Automatic Feeding & Efficient DryingEquipped with an automatic feeding unit and a dedicated UV lamp with cooling, this machine streamlines the coating process from start to finish. The automatic feeding system enhances productivity by ensuring steady material supply, while the UV drying guarantees rapid curing and high-quality output, even during continuous operation.

Flexible Coating Modes & Substrate CompatibilityChoose between roller or blanket coating modes for both spot and full UV coverage, accommodating various substrate thicknesses from 0.1 mm to 0.8 mm. The machine supports not only paper, but also board and plastic, making it versatile for diverse production needs in packaging and printing industries.

Advanced Control and CustomizationFeaturing a computerized PLC control panel and advanced color management system, users benefit from precise adjustments and reliable performance. The machine structure is built heavy-duty for durability, and options for customization ensure it can be tailored to specific operational requirements.

FAQs of UV Coating Machine Komori:

Q: How does the automatic feeding unit benefit the UV coating process?

A: The automatic feeding system ensures continuous and smooth material supply, reducing manual intervention and enhancing productivity for high-volume UV coating applications.

Q: What types of materials can be coated with the Komori UV Coating Machine?

A: This machine accommodates paper, board, and plastic substrates, with thicknesses ranging from 0.1 mm to 0.8 mm, allowing flexible production suitable for various print and packaging requirements.

Q: When is it ideal to use spot versus full UV coating with this machine?

A: Spot UV coating is optimal for emphasizing specific design elements, such as logos or graphics, while full UV coating provides overall protection and high-gloss finishes for entire surfaces. The machine enables both modes through selectable coating options.

Q: Where can the UV Coating Machine Komori be installed for optimal performance?

A: It is best installed in professional print shops or packaging facilities with stable air supply (0.6 MPa), appropriate voltage (380V/50Hz), and within the recommended working temperature range of 5C to 35C for consistent output and safe operation.

Q: What is the process for switching between roller and blanket coating modes?

A: Operators can easily adjust the coating mechanism based on the job requirements, using the PLC control system to select either roller or blanket coating mode. This flexibility simplifies transitioning between different coating styles.

Q: How does the advanced color management system improve print quality?

A: The color management system ensures precise color control, delivering consistent quality and vibrant results across both spot and full UV coatings, which is essential for branding and high-value print products.

Q: What are the benefits of choosing this machine for large-scale UV coating tasks?

A: Users gain reliable high-speed output (up to 5,000 sheets/hour), heavy-duty construction for longevity, automatic operation for reduced labor, and customizable features to meet specific project demands, ensuring maximum efficiency and profitability.