UV Coating Machine - Planeta

UV Coating Machine - Planeta

Features:

- Heavy duty construction

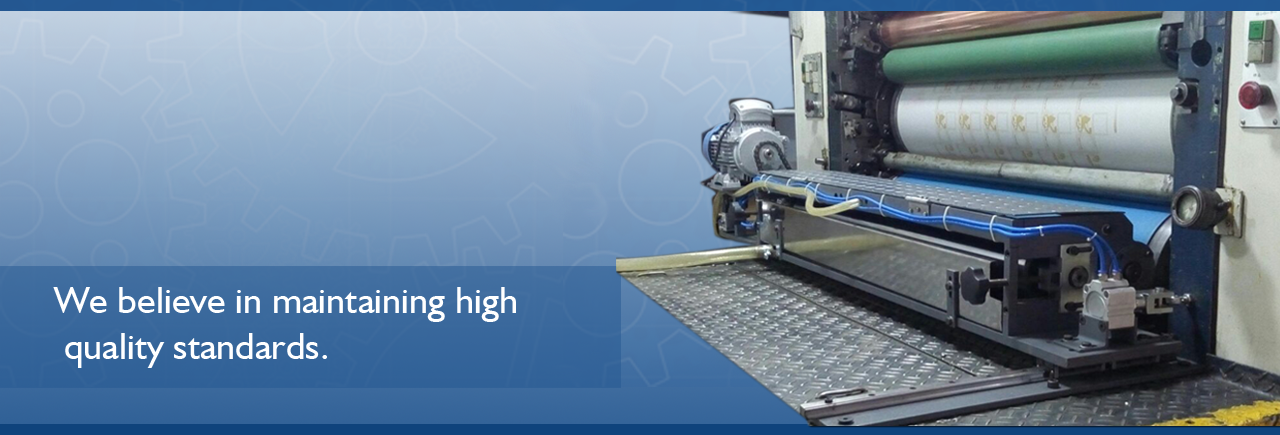

- Manual retraction system to change between printing and coating

- Independent AC motor and frequency drive

- Pneumatic Impression synchronized with main machine

- Varnish recirculation system with drip tray

Advantages:

- Uniform coating thickness with greater efficiency and repeatability.

- Easy to register and high production.

- Full as well as Spot Varnishing possible.

- Printing features of the main machine remains unchanged, as the system is independent.

- The total investment is negligible as compared to other options.

- Can be fitted on sheet fed offset of any make and size.

- Custom engineered to fit individual press.

Options:

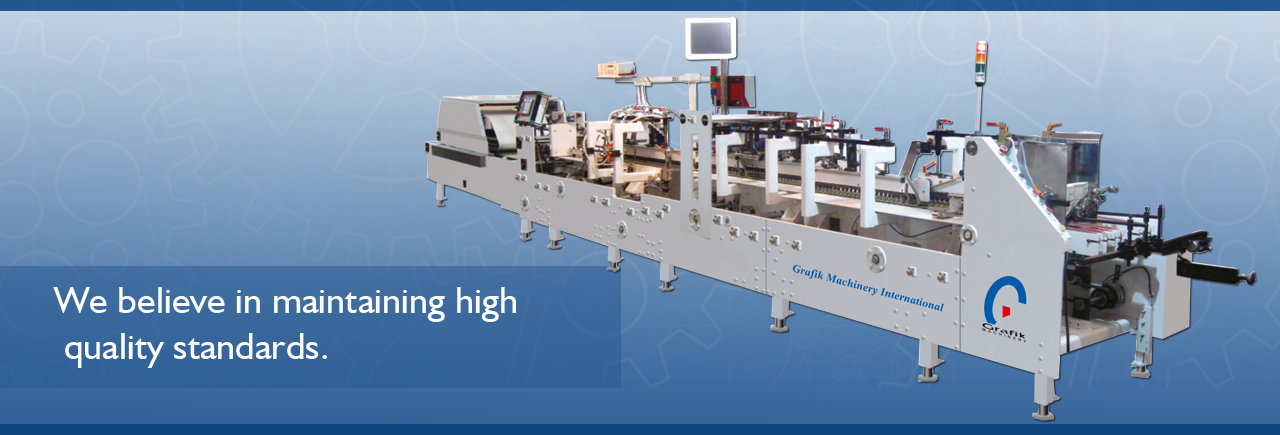

Advanced Automation & ControlThe Planeta UV Coating Machines fully computerized PLC with a user-friendly touchscreen panel makes operation straightforward and versatile. With adjustable speed and digital color management, the system optimizes productivity and ensures uniform coating across all projects, accommodating both standard and customized sheet sizes.

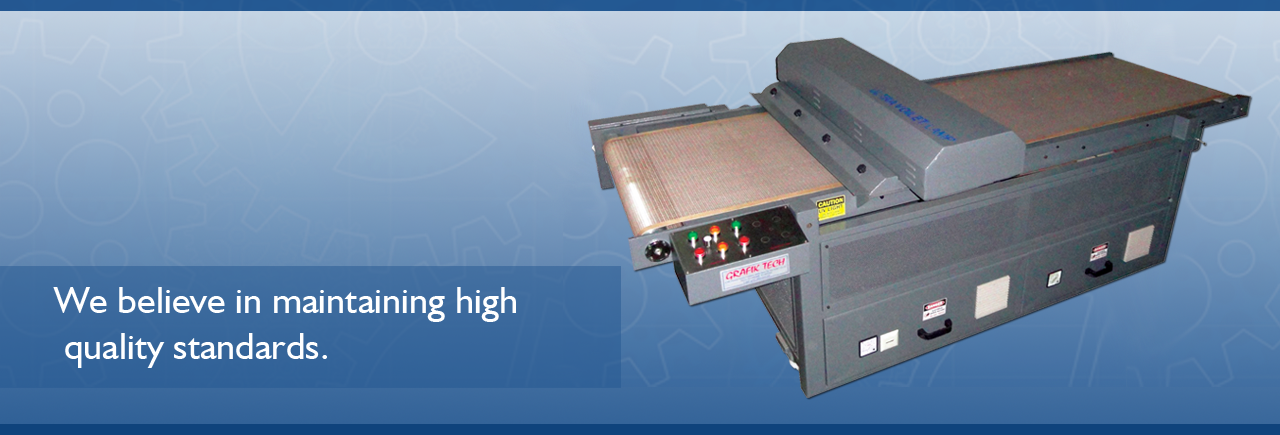

Exceptional Performance & VersatilityDesigned to handle materials ranging from thin paper to heavier nonwoven substrates (0.1 0.6mm), the machines automatic suction feeder facilitates smooth and jam-free feeding. The robust roller coater with air knife technology delivers even UV curable coatings for a variety of print directions on both standard and bespoke jobs.

Efficient Drying & Noise ControlEquipped with powerful UV lamps and integrated cooling fans, the Planeta dries coated sheets rapidly, supporting outputs of up to 4000 sheets per hour. Meanwhile, state-of-the-art engineering keeps operational noise levels below 72 dB(A), fostering a safer and more comfortable working environment.

Comprehensive Safety & Robust ConstructionOperator safety is prioritized with features such as emergency stops, safety guards, and high-strength stainless steel body construction. The design ensures reliability, low maintenance, and long service life, matching the demands of distributors, exporters, and manufacturers seeking dependable machinery in India.

FAQs of UV Coating Machine - Planeta:

Q: How does the Planeta UV Coating Machine automate the coating process?

A: This machine utilizes a computerized PLC system with a touchscreen panel and automatic suction feeder, enabling fully automatic operation. The variable frequency drive ensures smooth belt movement, while the digital panel allows dynamic adjustment of speed and color management, simplifying overall workflow.

Q: What materials and sheet sizes can the machine handle?

A: The machine is designed for paper, cardboard, and nonwoven materials with thicknesses between 0.1 to 0.6 mm. It accommodates a minimum sheet size of 320 x 450 mm and a maximum sheet width of 24 inches (610 mm), with standard or customized settings to suit diverse production needs.

Q: When is it beneficial to use the high-power UV drying system?

A: The high-power UV lamp, paired with cooling fans, is ideal for high-volume production, ensuring rapid drying of UV curable coatings. This results in shorter turnaround times and higher productivity, especially when operating at speeds up to 4000 sheets per hour.

Q: Where is the Planeta UV Coating Machine typically installed?

A: The machine is commonly installed in commercial print shops, packaging plants, and specialty finishing facilities across India. Its sturdy dimensions (3600 x 1300 x 1400 mm) and customizable configuration fit both industrial and mid-sized production environments.

Q: What is the coating method used and how does it benefit the application?

A: The Planeta employs a roller coater in combination with an air knife, providing uniform, precise UV curable coatings. This method enhances surface finish, protection, and visual appeal, supporting a variety of print directions and sheet surfaces.

Q: How do the safety features protect operators during usage?

A: Integrated emergency stops and safety guards are standard, preventing accidents during operation and maintenance. The stainless steel construction and high-strength components further ensure safe, reliable long-term use.

Q: What are the advantages of a fully automatic, computerized UV coating machine?

A: Fully automatic control reduces the risk of human error, increases throughput, and ensures consistent quality. The programmable logic, digital adjustments, and automated feeder allow efficient handling of large jobs with minimal supervision, benefiting manufacturers and suppliers seeking operational excellence.