UV Coating Machine Roland

UV Coating Machine Roland

Features:

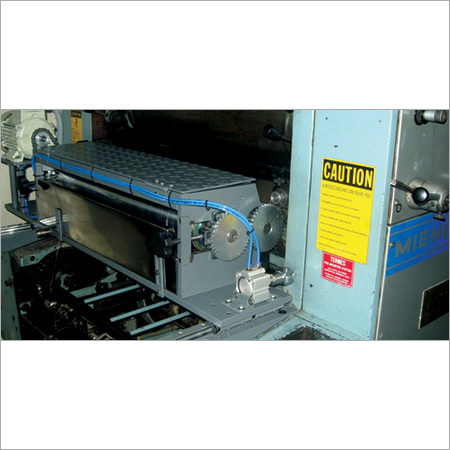

- Heavy duty construction

- Manual retraction system to change between printing and coating

- Independent AC motor and frequency drive

- Pneumatic Impression synchronized with main machine

- Varnish recirculation system with drip tray

Advantages:

- Uniform coating thickness with greater efficiency and repeatability.

- Easy to register and high production.

- Full as well as Spot Varnishing possible.

- Printing features of the main machine remains unchanged, as the system is independent.

- The total investment is negligible as compared to other options.

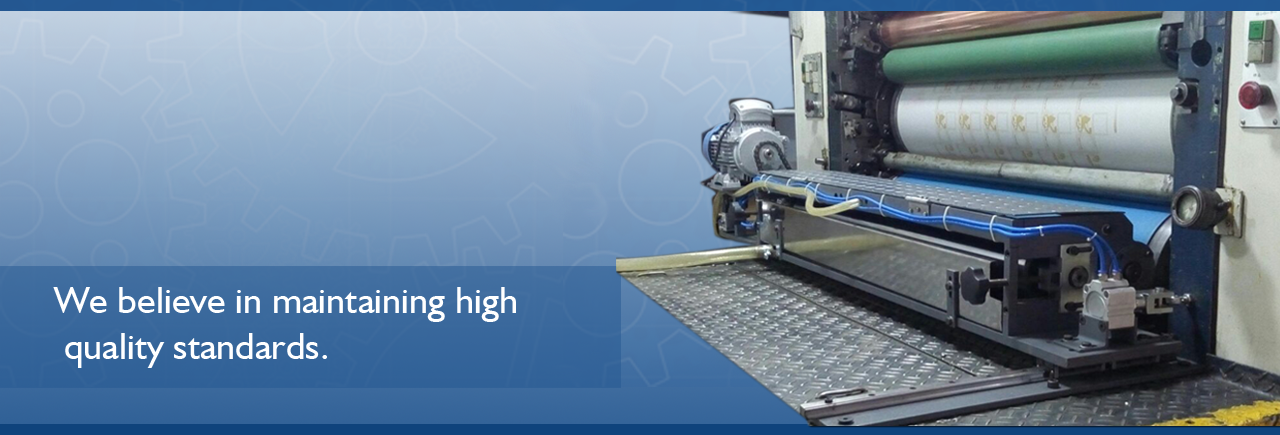

- Can be fitted on sheet fed offset of any make and size.

- Custom engineered to fit individual press.

Options:

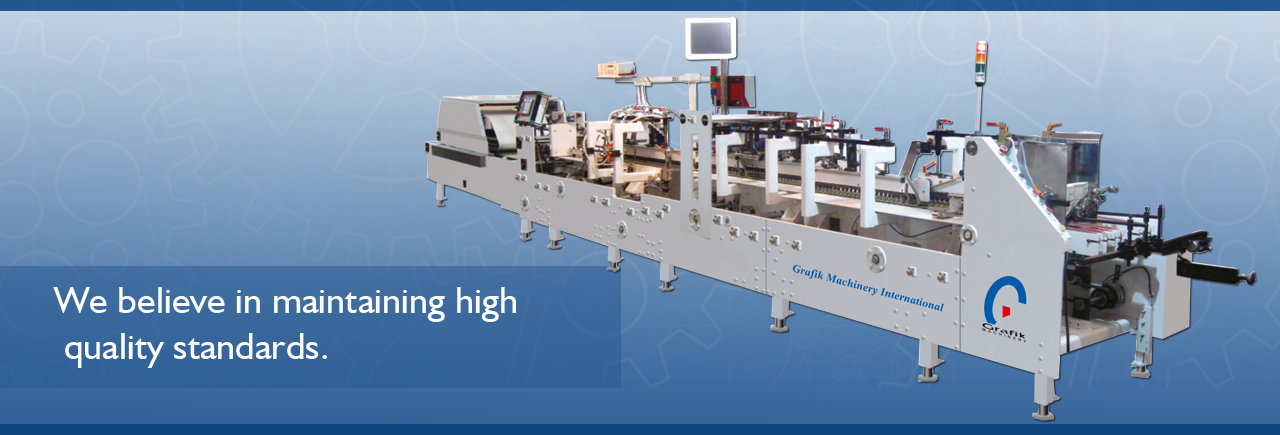

Exceptional Versatility and EfficiencyThe Roland UV Coating Machine is designed to process a wide range of sheet sizes with customizable settings. Its automatic feeding system and computerized PLC control enable high-capacity performance without sacrificing precision or finish quality. Operators can select from high gloss, matte, or satin finishes, optimizing the machine for any project requirements.

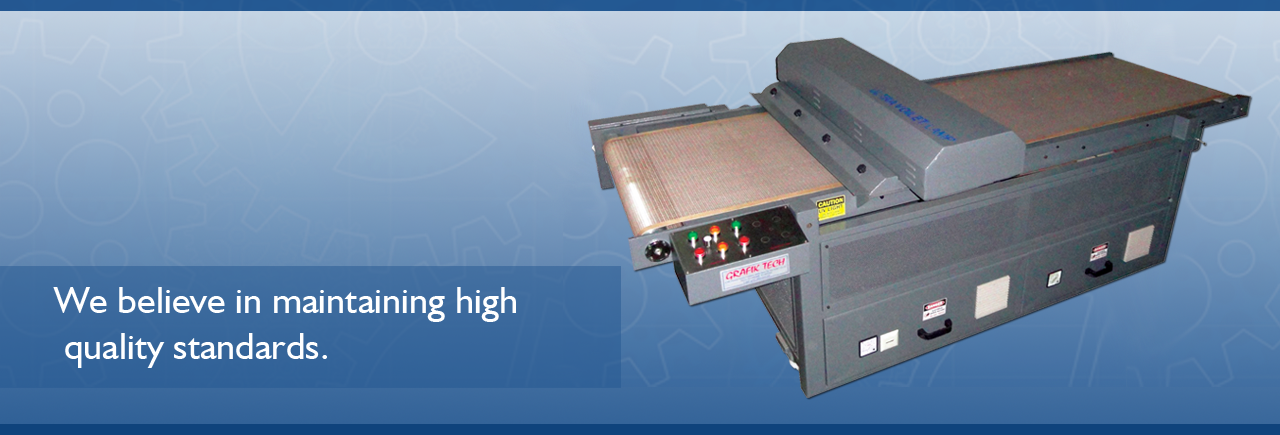

Advanced Safety and User-Friendly OperationThis machine prioritizes safety and ease of use with emergency stop functions and overload protection integrated into the design. A user-friendly touchscreen panel allows for real-time adjustments, ensuring that settings like coating thickness and color management are easily monitored and controlled. The automated features minimize operator intervention, enhancing workflow efficiency.

Ideal for Diverse Printing EnvironmentsWhether used for packaging, catalogs, or commercial offset prints, the Roland UV Coating Machine thrives in a variety of professional print shops. Its robust construction, noise-reduction (under 72 dB), and high-speed drying lamp make it a reliable solution for exporters, manufacturers, distributors, and suppliers across India. The machine is customizable to fit specific operational needs.

FAQs of UV Coating Machine Roland:

Q: How does the coating thickness adjustment work on the UV Coating Machine Roland?

A: The machine offers a fully adjustable coating thickness range from 5 to 50 microns. You can set the desired thickness using the touchscreen control panel, allowing for precise application of both gloss and matte finishes to suit different project requirements.

Q: What types of applications can this UV coating machine handle?

A: This machine supports gloss and matte coatings for offset print jobs, packaging materials, and catalogs. Its functionality makes it ideal for high-volume commercial printing and finishing workshops, ensuring a premium protective finish on a variety of paper and board substrates.

Q: When should the emergency stop and overload protection features be used?

A: The emergency stop should be activated immediately if you notice any unsafe condition or operational irregularity. Overload protection engages automatically when excess load or abnormal function is detected, safeguarding both the operator and the equipment from potential harm.

Q: Where is the UV Coating Machine Roland suitable for installation?

A: This machine is best installed in professional printing environments, such as commercial print shops, packaging producers, or catalog manufacturers. Its customizable size and moderate noise level make it suitable for most industrial settings, provided they offer three-phase 380 V power supply.

Q: What is the process for using digital color calibration and PLC control on this machine?

A: Digital color calibration ensures consistent color tone during coating, while the PLC-controlled system allows precise adjustments to operating parameters. The interface on the touchscreen guides operators through setup, calibration, and monitoring, simplifying the process and improving output quality.

Q: How does the machine benefit my production workflow?

A: With automatic feeding, high-speed processing (up to 10,000 sheets/hour), and instant UV drying, this machine improves throughput and reduces manual labor. The result is a faster turnaround on large orders, minimal downtime, and consistently high-quality finishes.